Home | eCommerce Solutions | Automated Package Sortation Machines

Optimize your eCommerce fulfillment with Tension’s line of sorting technology. Our sorters are designed with efficiency and maximum package throughput in mind, yielding:

A Tension Polybagger packs soft and durable goods, requiring minimal employee training while delivering maximum labor efficiency.

The ergonomic, horizontal infeed/exit polybagger combines the convenience of a handy work table and an integrated takeaway conveyor with the functionality of an easy-to-use Sharp MAX 20 packaging system. The HPC-H4 simultaneously offers a small footprint and large bag capacity of up to 20″ wide x 30″ long, ensuring an easy integration into your distribution center. Its 6″ pass through meets most standard order fulfillment needs. Add an optional 10″ pass through provides a solution that handles large items.

The Z1 is a zoned high-speed bi-directional transfer sort module that handles a wide variety of ecommerce and B-to-B cartons and polybag packages. With rates of up to 30 packages per minute, the zoned divert provides continuous contact surface across the zone to handle small and light weight packages. An easy to use HMI gives you lane divert choice control and verifies that packages were sorted to the proper gaylord.

The ergonomic, horizontal infeed/exit polybagger combines the convenience of a handy work table and an integrated takeaway conveyor with the functionality of an easy-to-use Sharp MAX 20 packaging system. The HPC-H4 simultaneously offers a small footprint and large bag capacity of up to 20″ wide x 30″ long, ensuring an easy integration into your distribution center. Its 6″ pass through meets most standard order fulfillment needs. Add an optional 10″ pass through provides a solution that handles large items.

The Z1 is a zoned high-speed bi-directional transfer sort module that handles a wide variety of ecommerce and B-to-B cartons and polybag packages. With rates of up to 30 packages per minute, the zoned divert provides continuous contact surface across the zone to handle small and light weight packages. An easy to use HMI gives you lane divert choice control and verifies that packages were sorted to the proper gaylord.

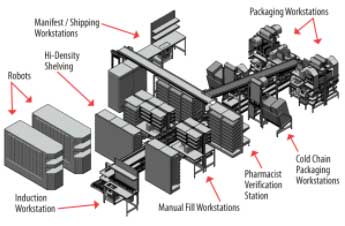

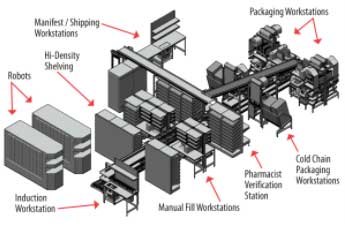

Tension provides customized software solutions which will integrate seamlessly in your eCommerce packaging operation. Our smart software is developed to communicate with the different systems customers have in place. Plus, it uses common design platforms to make it easier for operators to transition from multiple workstations.

Packaging Materials