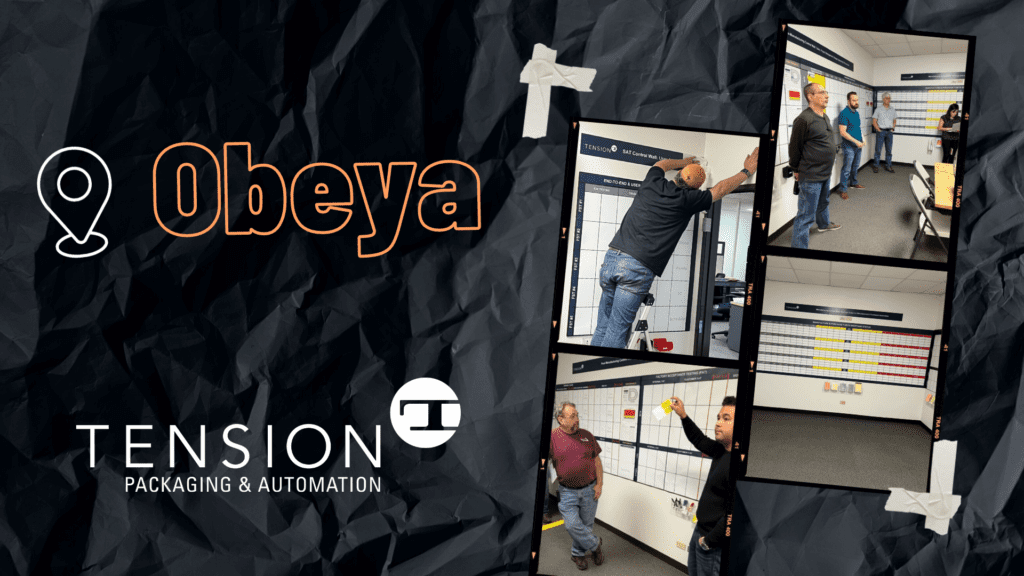

Process Spotlight: Obeya Launch

Tension Packaging & Automation’s “Big Room”

The road to delivering for our customers begins with strengthening our core capabilities, creating transparency, healthy accountability, real-time problem solving as a culture, and embracing a continuous improvement mindset. With these goals in mind, the Tension Packaging & Automation team officially launched our Obeya room earlier this year.

Big Picture of the Big Room: What is Obeya?

Obeya, a Japanese term that means “big room,” is an advanced Lean concept created by Toyota in 1993 during the production of their Prius model; it is a dedicated space for structured coordination and problem solving on our most critical customer issues.

An Obeya room:

- Brings the organization together in a single place.

- Enables our entire team to see the same set of facts.

- Provides a way for us to visually manage needs versus resources.

- Helps us to build strategies based on what is happening at the precise moment.

- Reinforces a common purpose and alignment of goals at every level of the organization.

Overall, our Obeya room helps us visualize the current situation in as close to real-time as possible. It does so in a way that all decision-makers can see the big picture and assess the true healthiness of our operations. It enables team collaboration, Lean operations, project management and ultimately customer satisfaction. Obeya brings our entire organization together to visually manage projects, balances demand to available capacity, enforces problem-solving as a process, and enables us to act quickly to achieve “takt” (i.e., the heartbeat of our organization).

How Does Obeya Work?

An Obeya room is divided into four major sections:

- Pre-Manufacturing – Sales incoming, order kick-off, long-lead item design release, engineering design release, purchasing and routings release.

- Procurement/Manufacturing – In-house machining and fabrication and purchased parts status.

- Post-Manufacturing – Kitting, assembly, final acceptance testing (FAT), crating, final detail inspection and invoicing.

- Commissioning – Site Acceptance Testing (SAT) and End-to-End Testing (E2E).

These four sections represent the entire life cycle of a project, and each job card represents the critical milestones and discrete deliverables required to achieve 100% quality and on-time delivery.

Obeya incorporates the concept of “slotting” demands into available capacity at every phase and activity of the projects. A Project Manager owns the overall execution of the projects in process; however, every function plays a critical role for their respective responsibilities. It is a true collaborative tool that brings the whole organization together as one.

Visualizing Continuous Improvement

The entire room is a visual management tool with intuitive visual cues throughout to help level the demand (“heijunka”), smooth production flow (“nagara”) and create pull systems as we seek to efficiently optimize the use of our resources and deliver value to our customers. It also highlights and exposes problems at each phase of the project life cycle and reinforces the continuous improvement culture.

What Does Obeya Mean for Our Customers?

Obeya provides us with one room, one system and one view of the sequence of work throughout our entire organization to help us meet customer deliverables (and ultimately provide them with highly satisfying experiences!). With the implementation of Obeya, our goal is to achieve 100% on-time, on-budget and on-quality customer deliverables.

Watch Obeya at Work

Take a live look at Obeya in our latest video here.

Contact Us

Obeya is just one example of many big things going on at Tension Packaging & Automation. Contact us to see what all the excitement is about and to discuss how we can aid your operations with automated packaging equipment for eCommerce & order fulfillment or pharmacy.