With global parcel volumes projected to double by 2025, selecting the right packaging equipment is crucial for handling increased demand. Heat seal packaging offers strong, weather-resistant seals ideal for clothing and soft goods, while cold seal packaging is perfect for dense items like books and electronics, offering cost and productivity benefits. Tension Packaging & Automation provides tailored solutions to optimize your operations and meet your growing needs.

According to a recent study, global parcel delivery volumes will increase by 100% by 2025. In addition to their annual peak season rushes, retailers and order fulfillment companies have a need to prepare for greater package volumes to come over the next few years.

When choosing equipment for your operations – and especially as you plan for growth – understanding the difference between heat seal and cold seal for packages can help guide your overall logistics strategy.

What is Heat Seal Packaging?

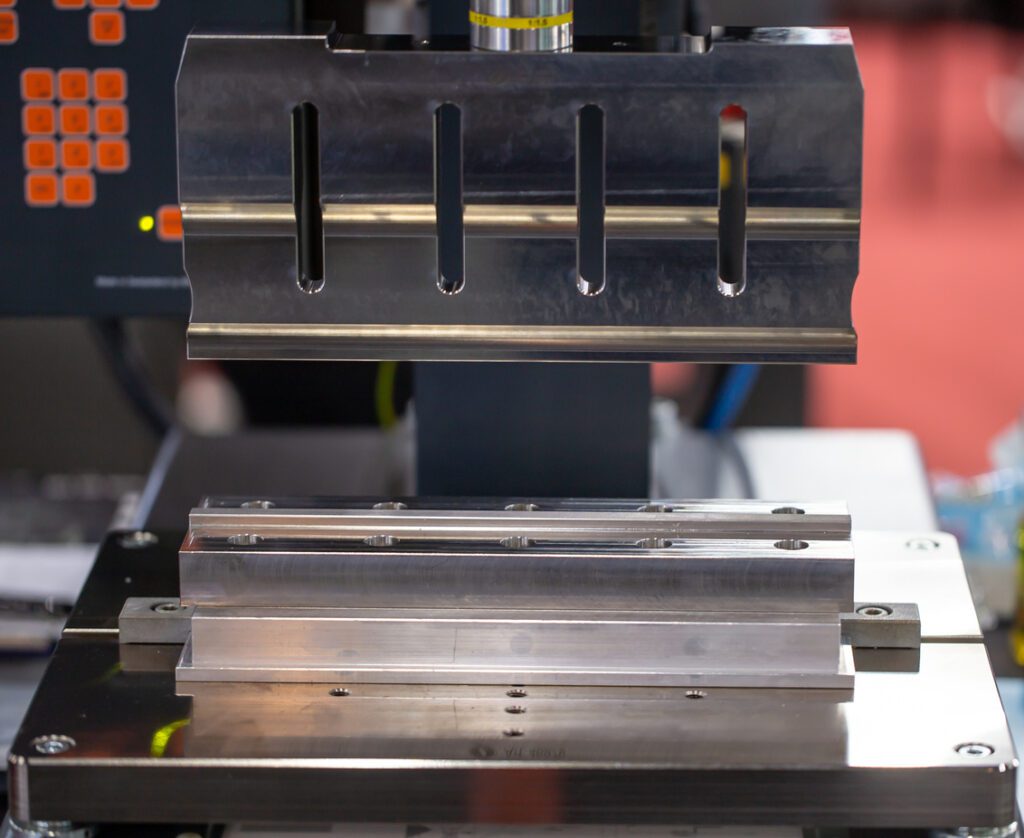

As the name implies, heat seal packaging uses heat to melt the sides of film packaging together to create a seal. In packaging applications, a heat seal can be used to both create a bag from two sheets of poly film and/or to secure the bag closed.

Heat Seal Benefits

- Protective Material: This material provides a strong package that helps to protects contents from harsh weather conditions, such as rain or snow (and the lighter weight material can possibly reduce shipping costs).

- No Adhesives Required: Because a heat seal uses heat to create the seal, there is no need for special pressure-sensitive adhesives.

- Increased Productivity: Using one of Tension’s automated heat seal solutions, you can pack and prepare 8-16 packages for shipment per minute, on average, vs. 1.5 packages per minute using a hand packing method. Additionally, the variable length system helps create a right-sized package that could save you on shipping costs.

What is Cold Seal Packaging?

Cold seal packaging refers to water-based adhesives that are used to seal paper (e.g., kraft corrugate) and film packaging material. Cold seal is a self-sealing type of closure, only requiring pressure to create the seal on a package.

Cold Seal Benefits

- Product Protection: Box-style packages* created from a cold seal eliminate the need for void fill, which creates increased protection for products inside.

- Increased Productivity: Keep your machine running fast with easy-to-use features like batch processing or length adjustments for variable sized packages with capabilities of up to 8-16 packages for shipment per minute.

- Cost Controller: Because cold seal packaging equipment requires no heating elements, it reduces costs related to electrical consumption.

Heat Seal vs. Cold Seal: Who Uses It?

A cold seal is ideal for companies packaging harder, dense products, such as books, CDs, DVDs or video games. Conversely, a heat seal is an ideal solution for companies packaging clothing, soft goods, shoes and other boxed items.

Contact Us

All packaging equipment is not created equal: Your products often dictate your seals and other packaging needs. Contact an expert at Tension to learn about solutions that can help optimize your productivity.