Packaging and Shipping Automation: Choose a Partner, Not Just a Vendor

When you’re evaluating fulfillment automation solutions for eCommerce or pharmacy operations, it’s easy to focus on the machinery. Specs, cycle

The Pregis MAX-PRO 18™ Automatic Packing Machine is designed to significantly boost your packaging productivity, handling packages up to 18″ wide with an 8″ pass-through. This newly redesigned polybag machine delivers faster run times and substantial productivity gains, while its compact footprint easily integrates into existing modular systems, saving valuable floor space. Equipped with advanced diagnostics for predictive maintenance, the MAX-PRO 18™ monitors internal components, alerting technicians to potential wear before issues arise, and reducing downtime. The user-friendly HMI, inspired by smartphones, simplifies operation, and the machine’s use of cost-effective, off-the-shelf parts further reduces operational costs. Improve your packaging process and elevate efficiency with the MAX-PRO 18™ Automatic Packing Machine.

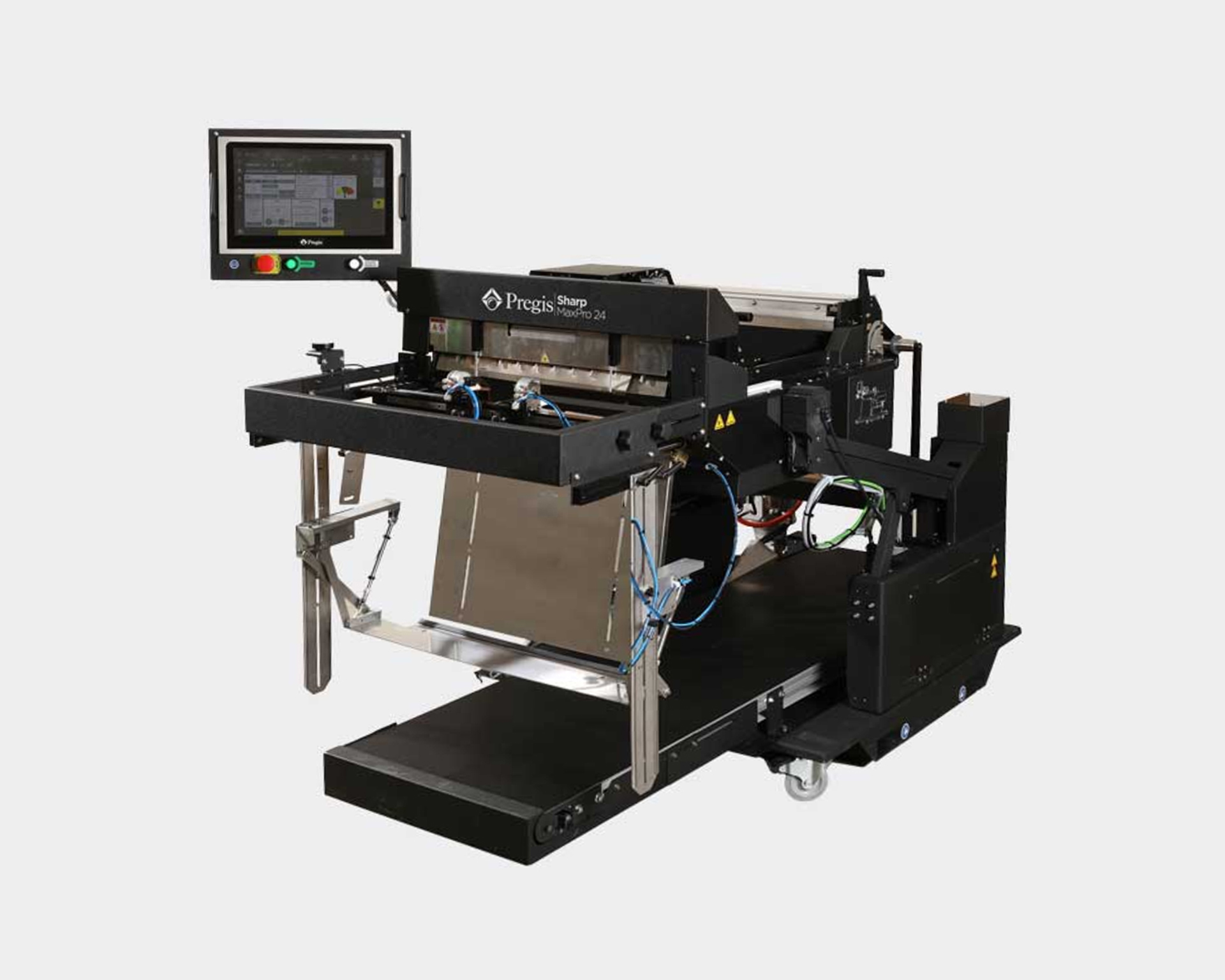

The Pregis MAX 24™ packaging system is the ideal solution for efficiently handling large contents, completing the entire packaging process in just seconds. This advanced poly bag machine significantly boosts seal packaging speeds with its vacuum-assisted technology, ensuring that the next bag is always ready for seamless operation. The MAX 24™ offers huge gains in throughput, delivering high-quality, reliable packaging for every job. With easily adjustable seal flattener settings and job recall capabilities stored in the HMI, operators can switch tasks effortlessly without manual adjustments. Other features like the convenient drop shelf for quick bag changeovers and the lightweight aluminum jaw for reduced cycle times further enhance productivity. Troubleshooting is a breeze with the integrated PC-based system, which provides access to manuals and video clips directly on the HMI.

Monitors machine components, notifying technicians of potential issues before failures occur.

Fewer components for reduced downtime and easier maintenance.

Automatically detects and adjusts obstructions for safe operation.

Cost-Saving Design

Reduces costly shipping mistakes and minimizes maintenance with long-lasting heat-sealing mechanisms and off-the-shelf parts for easy repairs.

Integrated Troubleshooting

Manuals and video tutorials accessible directly on the touchscreen HMI for quick problem-solving.

High Throughput

Polybags are fed smoothly through the machine’s opening mechanism, increasing packaging speed and efficiency.

Efficient Sealing Process

Bag openers and vacuum assist expand the bag, allowing the user to place contents and securely seal the package.

Integrated Printing

Address and shipping information can be printed directly onto the bag, reducing operator involvement, and increasing packing rates.

Versatile Bag Options

Bags available on rolls or in boxes, with the latter holding more bags for less frequent reloading.

Employee Training and Support

Tension provides comprehensive training during setup and ongoing on-call support through a Tension Service agreement.

When you’re evaluating fulfillment automation solutions for eCommerce or pharmacy operations, it’s easy to focus on the machinery. Specs, cycle

What shippers need to know about the new regional delivery service — and how it may (or may not) fit

In the fast-paced, competitive environment eCommerce fulfillment, speed isn’t just an advantage — it’s a necessity. Yet, many fulfillment centers