Modular Automation: How to Start Small & Scale Big in Your Warehouse

Modular automation helps warehouses start small, reduce risk, and scale efficiently over time without costly system overhauls or operational disruption.

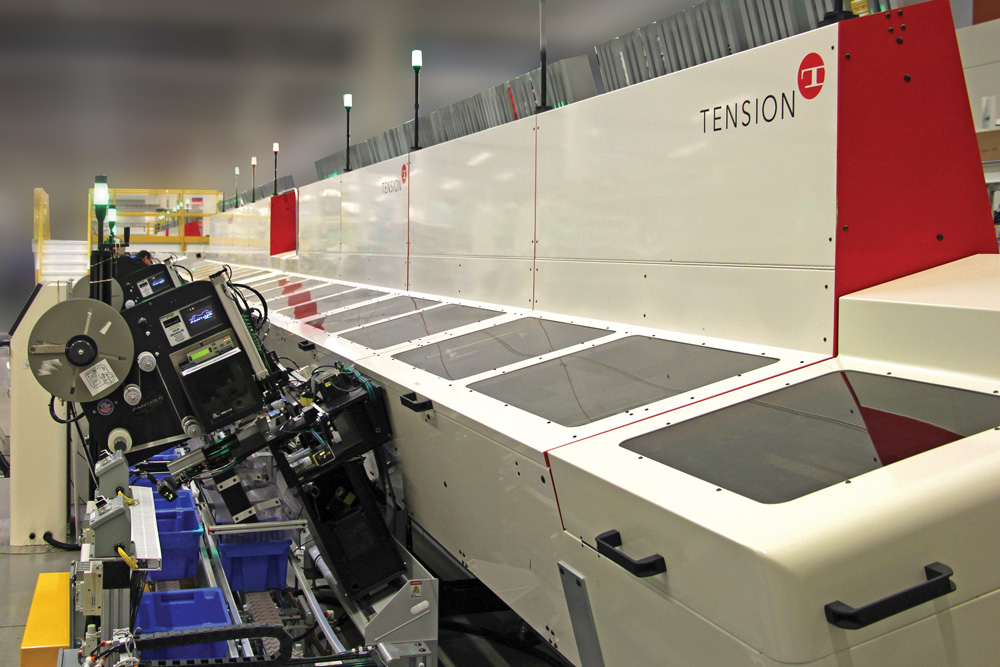

The Tension Linear Dispensing Unit (LDU) is a groundbreaking unit-of-use prescription dispensing machine designed to reduce costs and optimize pharmacy operations. By automating the dispense, label, and packaging process, the LDU enables pharmacies to handle more medications faster, in less space, and with fewer resources. Its advanced features include multi-stage verification for increased accuracy, the ability to handle irregularly shaped medications, and a tote conveyor system that seamlessly moves prescriptions to packing stations. With quick and easy loading and replenishment, the LDU boosts output and lowers the cost per script, making it an ideal solution for high-volume pharmacy automation.

The Linear Dispensing Unit (LDU) is a high-volume automated prescription dispensing and labeling system for unit of use items. Once prescriptions are verified through multi-stage scan technologies, a tote conveyor system transfers prescription orders from the LDU to PV2 and packaging stations.

The LDU features an auto-archiving system that records and validates medications, ensuring faster and more efficient downstream verification for accurate prescription fulfillment.

Capable of dispensing and labeling units of use and prepacking, the system is designed to handle square, round, or irregularly shaped items, offering flexibility in pharmacy operations.

The LDU system is available in multiple configurations, tailored to meet your pharmacy’s unique formulary, output, and space requirements, maximizing efficiency and scalability.

Multi-Step Verification for Accuracy

Automatically verifies medications using National Drug Code (NDC) and patient-specific labels, with additional verification post-labeling to ensure precision.

High-Output Dispensing

Handles dispensing, labeling, and verification for units of use and prepack products of varying shapes and sizes, boosting throughput for central-fill and mail-order pharmacies.

Efficient Workflow Management

Alleviates bottlenecks with auto-archiving, enabling pharmacists to verify medications virtually, speeding up downstream verification.

Customizable and Space-Efficient

Available in multiple configurations to fit your pharmacy’s space and output needs, while interfacing easily with traditional tote lines.

Auto-Reject and Continuous Operation

Features an auto-reject system to handle exceptions without halting production, keeping operations running smoothly.

Easy Stock Replenishment

Rear product loading slots allow for quick replenishment without slowing down the machine’s output, ensuring continuous operation.

Support and Training

Tension provides ongoing training, support, and access to spare parts, ensuring your system runs efficiently throughout its lifecycle.

Reduces Costs and Labor

Automates key processes, reducing the number of personnel needed and lowering overall operational costs.

Footprint (length x depth x height): 32′ x 9′ x 8′ square feet of space

Modular automation helps warehouses start small, reduce risk, and scale efficiently over time without costly system overhauls or operational disruption.

Summary As pharmacies expand their prescription volumes, outdated systems can become a bottleneck. Without scalable pharmacy automation systems, growing operations

When you’re evaluating fulfillment automation solutions for eCommerce or pharmacy operations, it’s easy to focus on the machinery. Specs, cycle