Modular Automation: How to Start Small & Scale Big in Your Warehouse

Modular automation helps warehouses start small, reduce risk, and scale efficiently over time without costly system overhauls or operational disruption.

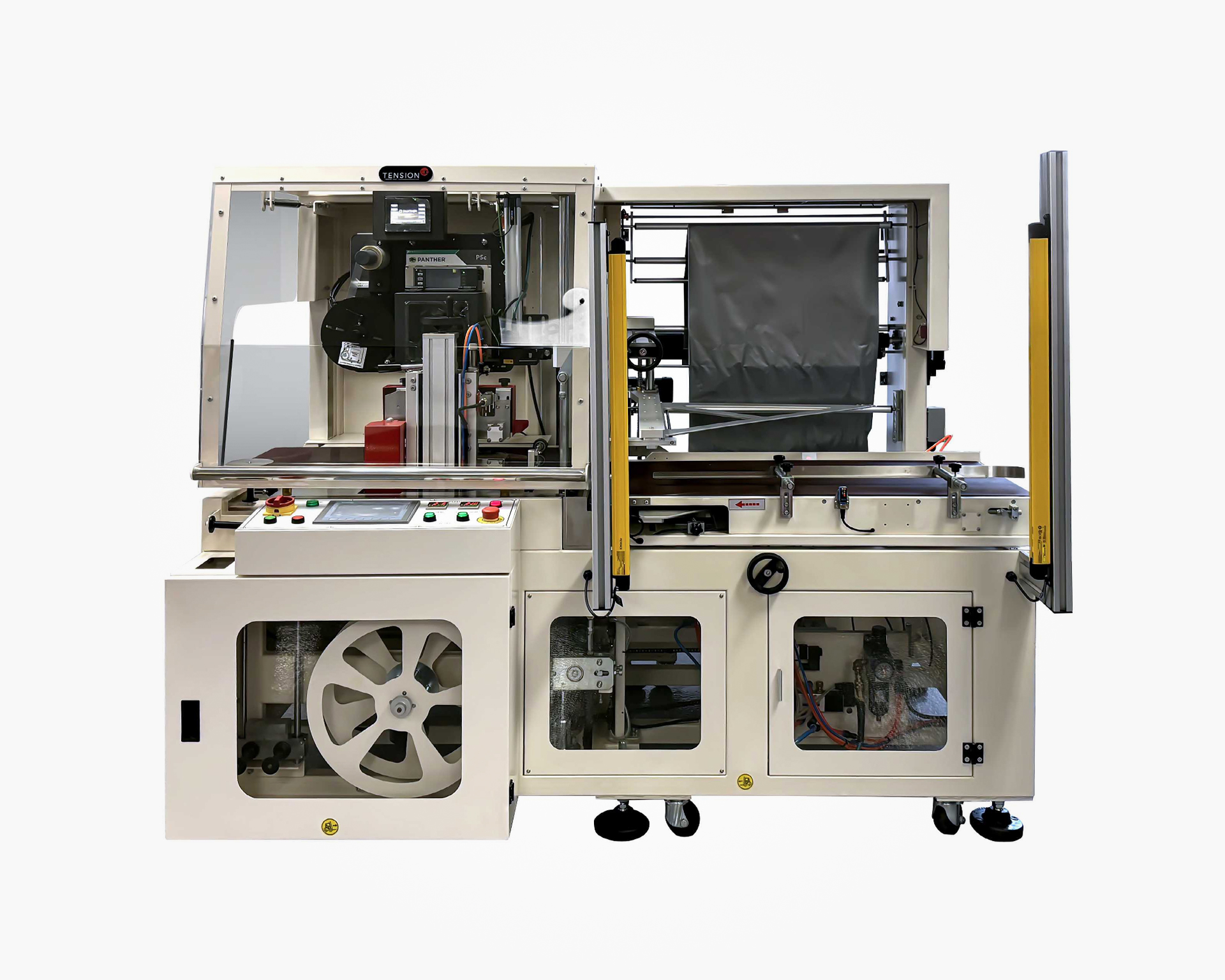

The HPS Variable Length Polybagging Machine offers a variable-length packaging solution for uniquely sized items like clothing, shoes, and soft goods. This advanced automated system creates perfectly sized packages, reducing waste and promoting sustainability with recycled consumables. Designed to streamline your shipping operations, the HPS polybag machine helps businesses increase efficiency while minimizing environmental impact. Discover how this innovative PolyBagging system can improve your order fulfillment process and improve your packaging workflow.

The HPS-300 is a variable length packaging system that accepts a continuous order stream, determines package length, applies a label and creates a finished package. It yields smaller, tighter packages that can lead to lower shipping costs.

HMI touchscreen is powered by TensionCONNECT software and features an intuitive, easy-to-navigate menu for operators.

using high-quality labeling technology. Clear, legible labels with consistent placement help drive accuracy throughout the shipping process.

1-to-1 indexing of scanned orders to printed bags ensures that the “next bag out” matches the order

Increased Productivity

The HPS-300 can produce 8 to 18 packages per minute so you can ship more in less time and improve customer satisfaction.

Reduced Shipping Costs

This system uses flat C-Fold polyfilm to create a tamper resistant package and reduce shipping costs.

Improved Package Protection

The heat seal method provides a strong seal and excellent protection against moisture, dust, and other contaminants, making it a good choice for products that need to be kept dry or clean.

Modular automation helps warehouses start small, reduce risk, and scale efficiently over time without costly system overhauls or operational disruption.

Summary As pharmacies expand their prescription volumes, outdated systems can become a bottleneck. Without scalable pharmacy automation systems, growing operations

When you’re evaluating fulfillment automation solutions for eCommerce or pharmacy operations, it’s easy to focus on the machinery. Specs, cycle