How a Sortation System Can Optimize Your Order Fulfillment Services

tensionapdev

on

January 18, 2023

The Role of Sortation Systems in Optimizing Order Fulfillment Services

The eCommerce industry is face paced, featuring order fulfillment as a critical factor of customer satisfaction. To meet customer demands and expectations, warehouses are increasingly turning to automated sortation systems to optimize their order fulfillment process.

When it comes to shipping, fast is no longer fast enough. Consumers who were impressed with Amazon’s two-day shipping now want shorter delivery times and lower shipping charges. Twenty-minute delivery windows may soon be the new standard for delivery times as adopters of quick commerce (Q-Commerce) gain traction in the grocery segment, which could soon expand to other retail industries. A recent study also revealed that 66% of online shoppers had abandoned their carts because of shipping costs.

Creating Operational Efficiencies with Sortation

As consumers want more for less, warehouses, distribution centers and order fulfillment operations are looking for ways to be more productive. One way to offer these efficiencies is through sortation systems for order fulfillment.

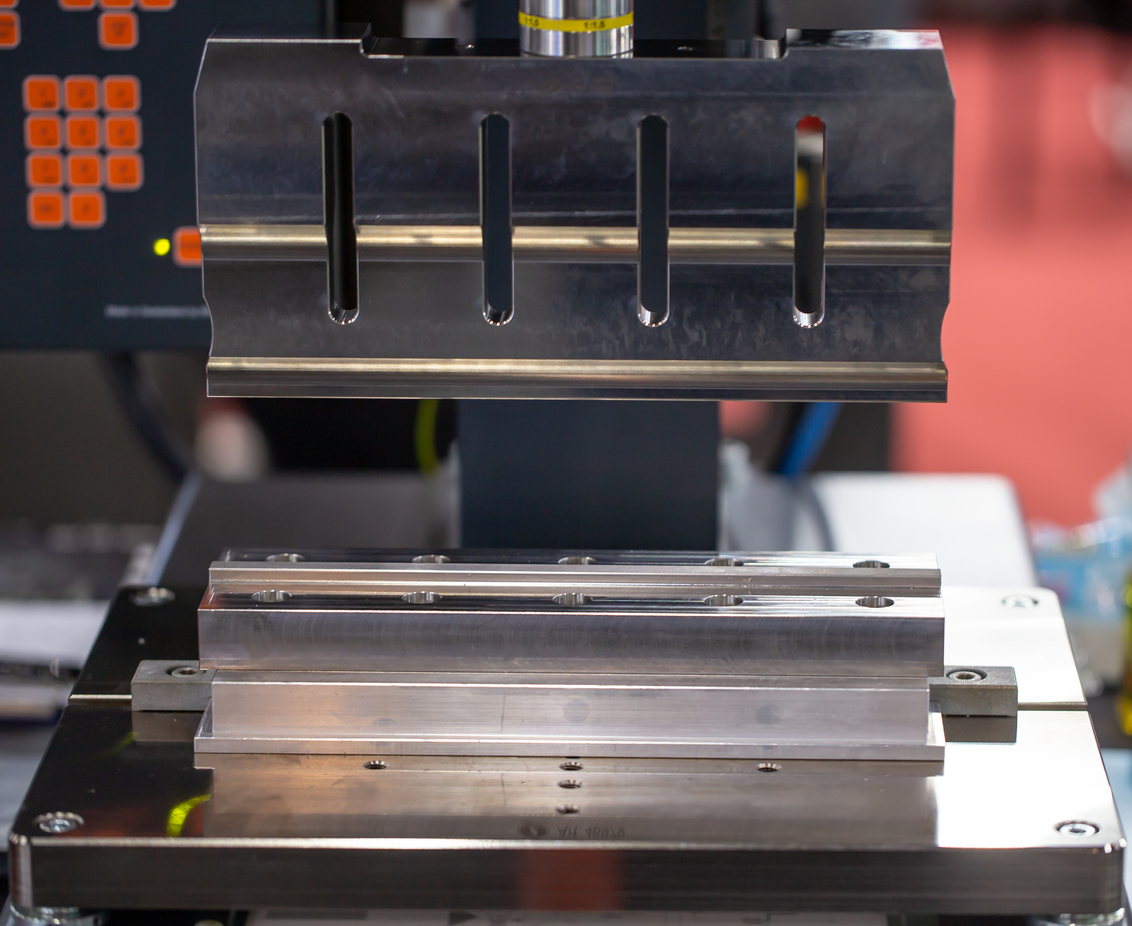

Items that have been packaged on our automated packaging equipment , travels to the sorter when the package is identified and diverted with the assistance of our TensionCONNECTTM software.

How a Sortation System Can Help Your Fulfillment Operations

Sortation systems can help optimize your order fulfillment operation by improving order accuracy and speed, reducing labor costs, and ensuring versatility and use of warehouse space. By automating the sorting process, you can process a high volume of orders with minimal resources and reduce the chances of errors occurring during the fulfillment process.

Benefits to using sortation systems in your order fulfillment operations include:

- Increased Speed: With routing that is completed in a fraction of the time compared to a manual process, a sortation system can help drastically improve item sorting rates.

- Improved Accuracy: A scanner automatically assigns the package to the correct carrier so your staff doesn’t have to.

- Decreased Labor Costs: With the added efficiencies a sortation system can provide, your staff can focus on other high-skilled areas that need their expertise.

- Better Use of Valuable Warehouse Space: Save floor space with a sophisticated, flexible design tailor-made for tight warehouses.

- Enhanced Versatility: Our sorters can handle nearly every size, shape and weight, including apparel, shoes, jewelry, pharmaceuticals, CDs, mail, books and small parcels.

What to Consider When Choosing a Sortation System

When choosing a sortation system for order fulfillment, several factors must be taken into consideration, including the type of products being sorted, the layout of the warehouse, budget, and ROI. These can have an impact on which sortation systems work best for your order fulfillment. Choosing the right sortation system for order fulfillment can greatly enhance efficiency, accuracy, and customer satisfaction, making it a critical decision for any warehouse or distribution center.

Choose Sortation Systems Designed to Grow With You

Compact and adjustable, our sortation system fits into small or large spaces, and can adjust to different modes or fulfillment channels. This system is also designed to grow in capacity, and is flexible enough to handle a changing product mix.

We work in an environment where the only constant is change. It’s an environment where responding to a more demanding customer is vital to your business. With increased fulfillment demands, an automated sortation system may just be the key to lasting success.

Contact Tension

Tension Packaging & Automation is a leader in complete packaging and automation solutions for the eCommerce and pharmacy automation industries. Our line of packaging equipment seamlessly integrates with sortation systems and related software to help rate-shop and select the best carrier at the best price.

Contact Tension today to discuss how we can help set up your eCommerce or pharmacy order fulfillment operation for success with the help of our sortation systems.