Breaking Bottlenecks: How Automation Solutions Improve Your Fulfillment Value Chain from Inbound to Outbound

emoloney

on

May 27, 2025

In the fast-paced, competitive environment eCommerce fulfillment, speed isn’t just an advantage — it’s a necessity.

Yet, many fulfillment centers find themselves facing a frustrating reality: bottlenecks that disrupt the flow at some point from inbound receiving all the way to outbound shipping.

Keeping the fulfillment value chain in balance is critical to long-term success. When operations like picking, packing and shipping aren’t aligned, bottlenecks form — leading to backlogs, overtime and late or missed shipments. If equipment downtime or failure occurs on top of that, the impact can multiply quickly.

The good news? Proactive planning and the right automation solutions help create a connected, resilient system that can absorb disruptions and keep your operation moving efficiently. With the right eCommerce fulfillment solutions, you can eliminate bottlenecks across the entire value chain — increasing throughput, reducing costs and setting your operation up for scalable growth.

Where Bottlenecks Begin — and How to Solve Them

Automation targets bottlenecks where they hurt most — saving time, reducing manual touchpoints and improving consistency.

In many fulfillment centers, a common bottleneck happens at the pack-out stations. As order volumes rise — especially during peak seasons — manual packing teams often struggle to keep pace with the increased picking rates. Even with efficient picking and inventory management upstream, the final packaging step can become a major constraint.

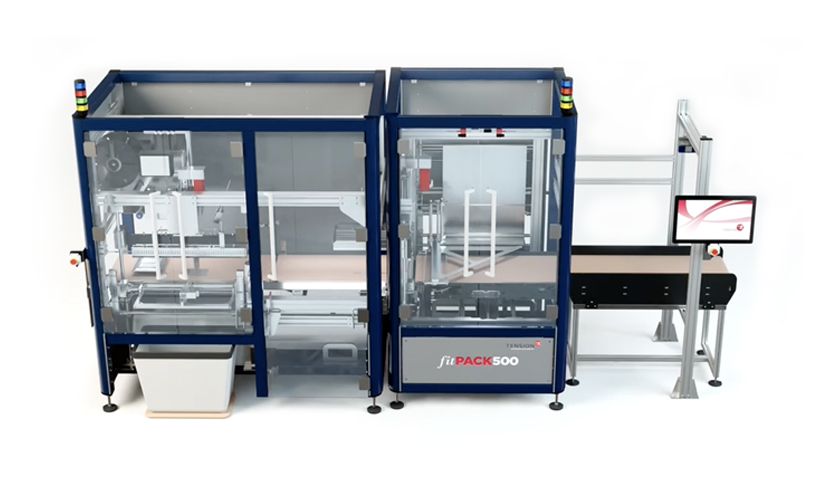

Automated bagging systems help resolve this challenge by increasing the speed and consistency of packing. Solutions like the fitPACK500TM automatically create right-sized bags for each order, eliminating the need for manual packing and reducing the chance of bottlenecks at the end of the line. This not only speeds up order throughput but also helps fulfillment centers avoid the costly cycle of overtime, temporary labor surges and delayed shipments.

Bagging for the Win: Why Right-Sized Packaging Matters

When it comes to improving throughput and cost-efficiency, right-sized packaging solutions like the fitPACK500 make a major impact:

- Speed Gains: The fitPACK500 automatically creates a bag sized perfectly for each order, minimizing waste and maximizing pack-out rates — allowing packaging to catch up with picking speeds.

- Shipping Savings: Smaller, right-sized bags reduce DIM (dimensional weight) surcharges from carriers — a hidden cost many fulfillment centers underestimate.

- Space Efficiency: The fitPACK500’s compact footprint frees up valuable warehouse space compared to bulky carton lines.

- Sustainability: With less void fill and packaging material, right-sized bags help reduce your environmental footprint while also saving costs.

By optimizing packaging as part of your larger fulfillment strategy, you gain speed, efficiency and bottom-line savings all at once.

Future-Proof Your Fulfillment with Smarter Solutions

Bottlenecks are costly — but preventable.

By taking a full-chain view of your warehouse operations, from inbound to outbound, you can identify where automation makes the biggest impact.

Solutions like fitPACK500 for right-sized packaging and tailored eCommerce fulfillment solutions help eliminate bottlenecks, lower shipping costs and set your operation up for long-term success.

Ready to rethink what’s possible in your fulfillment center? Learn more about Tension’s full range of eCommerce fulfillment solutions today. Contact us to get started.