Home | Pharmacy Automation Equipment and Packaging | Automation Systems

JumpStart and LDU-Flex pharmacy automation systems allow mail-order, central-fill, pet and specialty pharmacies to enjoy the benefits of pharmacy automation without a high minimum script threshold. Requiring low capital and minimum space, automated dispensing systems for pharmacies can help your pharmacy leapfrog the competition. Our pharmacy automation solutions grow with you. Improve your pharmacy workflow system today.

JumpStart pharmacy automation systems feature a center tote conveyor line, then includes processing stations and additional lines at multiple levels depending on your pharmacy’s configuration.

Benefits:

Traditional automated dispensing systems in pharmacies require operations personnel and pharmacists to move around the pharmacy and fill orders. With Tension JumpStart, our systems are designed to bring orders to your team, allowing it to be more efficient. Explore our pharmacy automations systems and contact us to learn more.

3 This is the entry-level pharmacy automation system that can be used with or without pill counting robots. • Unique, 2-Level circular tote ring rotates with tote stops at each workstation • Top level handles totes for order induction, dispensing and packaging • Lower level ring efficiently handles totes for Pharmacy Verification • The system fits in 1,000 sq. ft. and can process 1,000+ items per 8-hour shift

4 This is the entry-level pharmacy automation system that can be used with or without pill counting robots. • Unique, 2-Level circular tote ring rotates with tote stops at each workstation • Top level handles totes for order induction, dispensing and packaging • Lower level ring efficiently handles totes for Pharmacy Verification • The system fits in 1,000 sq. ft. and can process 1,000+ items per 8-hour shift

Supercharge your pharmacy by adding the high-volume JumpStart system with high-speed pill counting robots.

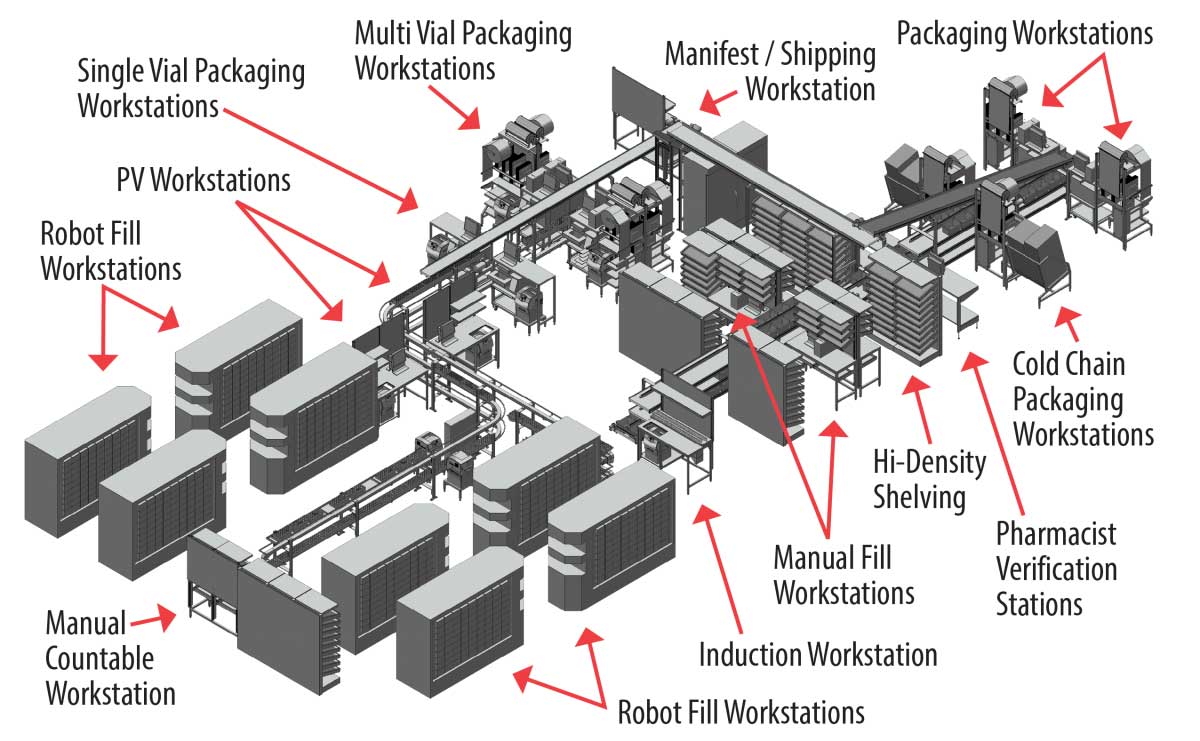

Packaging workstations, cold chain packaging workstations, pharmacist verification station, manual fill workstations, induction workstations, robot fill workstations, hi-density pharmaceutical shelving, manifest/shipping workstations, manual countable workstation, PV workstation, Single Vial Packaging (SVP) workstation, and multi-vial packaging workstations.

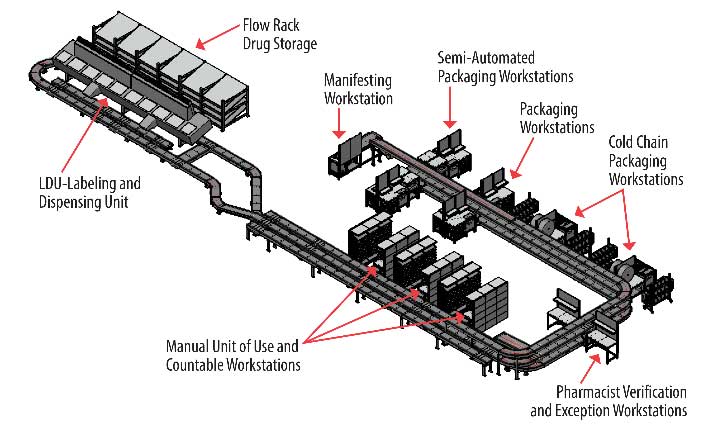

Designed specifically for those pharmacies requiring efficient and accurate dispensing of high-volumes of unit of use meds.

This software system manages the back-end processing of prescription and non-prescription items for orders delivered from a front-end environment. Tension PharmaPATH workflow software system accepts order requests that have been

fully confirmed, ready for processing. Then, it facilitates the prescription through dispensing, pharmacist verification (PV), packaging and manifesting.

Packaging Materials